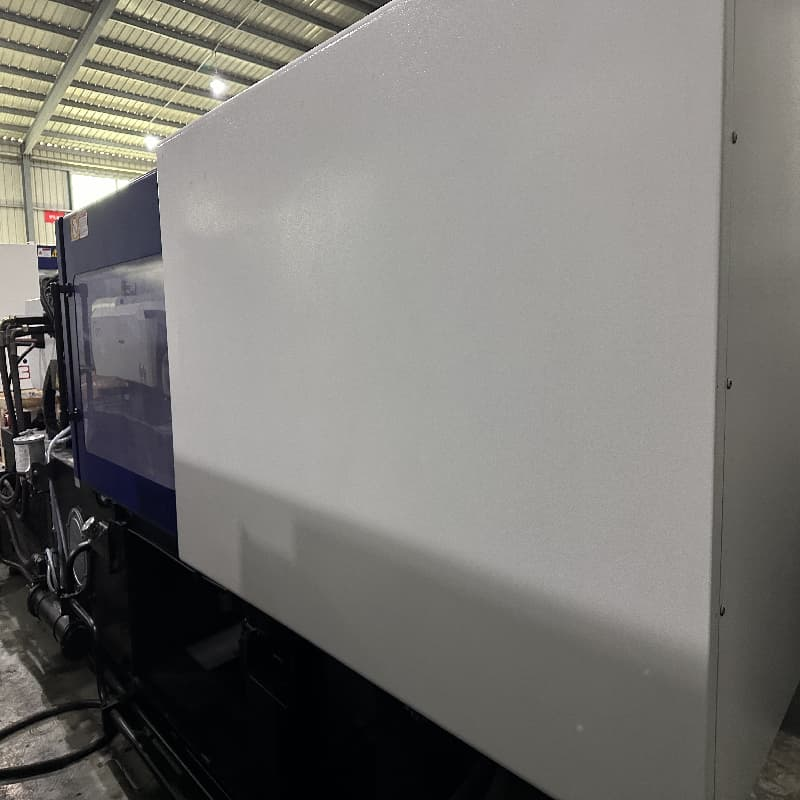

328T

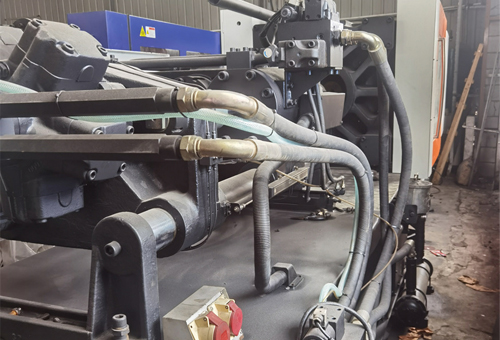

Chair Making Desktop Usb Cable Blow Vertical Plastic Injection Mold Injections Moulding Machine

Brand:

ChenHsong

Appearance:

Horizontal

Model Number:

328T

Stock:

≥1 pieces

Price:

$55,600.00

Product Details Display

Chair Making Desktop Usb Cable Blow Vertical Plastic Injection Mold Injections Moulding Machine

Equipment Parameters

Chair Making Desktop Usb Cable Blow Vertical Plastic Injection Mold Injections Moulding Machine

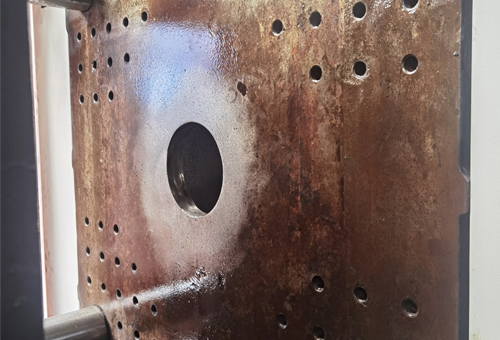

| Condition | Used |

| Style | Horizontal |

| Injection Rate (g/s) | 368 g/s |

| Machine Type | Hydraulic |

| Injection Weight (g) | 1000 g |

| Weight (KG) | 1200 kg |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Other |

| Showroom Location | None |

| Machinery Test Report | Not Available |

| Video outgoing-inspection | Provided |

| Core Components | Motor, Pump, Gear, PLC, Engine, Gearbox, Other |

| Year | 2017 |

| Working hours | more than 50000 |

| Place of Origin | Guangdong, China |

| Product name | Plastic Injection Moulding Machine |

| Keyword | Used Injection Molding Machine |

| Machine Type | Hydraulic |

| Machinery Test Report | Provided |

| Core Components | Motor, Gear, Engine, Gearbox, Screw |

| Used for | Tube connector, preform, caps, crates, toys... |

| After-sales Service Provided | Video technical support |

| After Warranty Service | Video technical support |

| Voltage | As customer required |

| Warranty | 1 Year |

| Parameters | BST-3000 | BST-3400 | BST-3850 | |

| Screw diameter | mm | 56 | 58 | 65 |

| Theoretical Shot weight | CM3 | 788 | 858 | 1192 |

| Shot weight | gram | 709 | 772 | 1072 |

| Clamping force | KN | 3000 | 3400 | 3850 |

| Toggle stroke | mm | 560 | 580 | 660 |

| Ejector stroke | mm | 160 | 160 | 160 |

| Space between tie bars | mm | 580*580 | 640*640 | 680*680 |

| Mould thickness | mm | 220-600 | 270-650 | 280-680 |

| Machine size | m | 6.5*1.8*1.8 | 6.7*2.0*1.9 | 7.0*2.2*2.0 |

| Machine weight | ton | 9 ton | 10.8 ton | 11.5 ton |

| Injection Molding Machine Standard Feature |

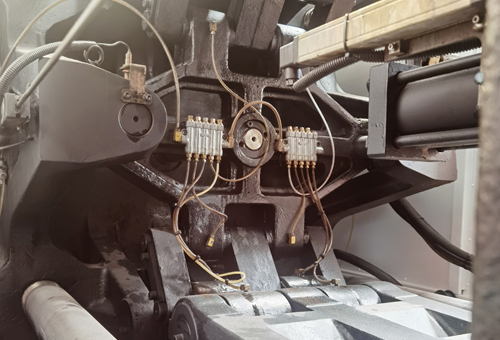

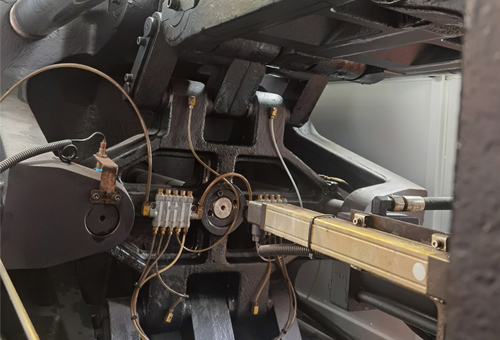

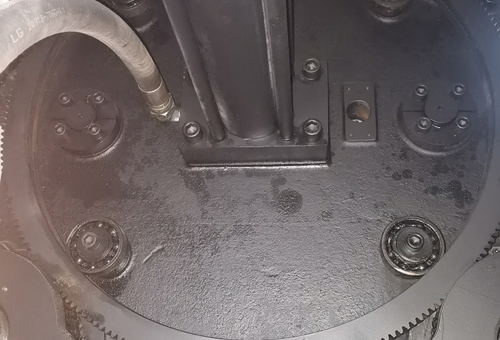

| CLAMPING UNIT |

| 1. New type 5-point toggle device with the advantage of stable movement curve and gentle shock 2. High-quality mold platen with enough intensity to ensure no out of shape if high-pressure clamping 3. Hard chrome plated high tensile strength tie bars made of superior alloy with a good wear and corrosion resistance ability 4. Wear-resistant guide for moving platen 5. Transducer control clamping stroke 6. Many step controls for speed and pressure of clamping and opening 7. Ejection device offer dwell, single, more, vibration function 8. Differential high-speed clamping 9. Low pressure mold protection function 10. Hydraulic mold height adjustment derived by gear with rough and fine operation 11. Mechanical and electrical dual safety interlock 12. Automatic centralized lubrication system with far pressure detector |

| HYDRAULIC UNIT |

| 1. Proportional pressure and flow control with the advantage of fine adjustment and high precision 2. Know-how manifold design, compact, reasonable and fast respond 3. Imported world famous hydraulic valves 4. Imported world famous hydraulic sealing rings 5. Import technology hydraulic hose and fittings 6. Low noise hydraulic system 7. Oil tank with inner stainless-steel container 8. Precision oil filter 9. Oil cooler |

| CONTROL UNIT |

| 1. The computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English language to display 2. World famous electrical components 3. Close-loop PID temperature control with the advantage of high precision. 4. Deviation preset between high and low temperature. And break control for temperature sensor. 5. Alarming system in case of cold start and no material in hopper 6. Transducer control the injection and opening stroke to accuracy of ±0.05mm 7. 99 steps speed control for increasing and reducing to suit for different technology demands 8. Self-diagnostic and trouble alarm function 9. Parameters lock function to avoid being changed 10. 100 sets of production parameters can be stored into the computer memorial software 11. Machine can record the quantity of products and automatically stop if up to the required quantity. 12. Emergency stop device 13. Alarm lamp |

Tags:

Do You Need Help Buying The Right Machine?

Let Our Experienced Sales Team Assist You. Fill Out The Contact Form With Some Of Your

Specifications And We Will Ensure A Member Of The Team Gets Back To You As Soon As Possible

To Discuss Your Requirements.

Let Our Experienced Sales Team Assist You. Fill Out The Contact Form With Some Of Your Specifications And We Will Ensure A Member Of The Team Gets Back To You As Soon As Possible To Discuss Your Requirements.

Let Our Experienced Sales Team Assist You. Fill Out The Contact Form With Some Of Your Specifications And We Will Ensure A Member Of The Team Gets Back To You As Soon As Possible To Discuss Your Requirements.

Fill In The Details Below And We Will Help You Find The Right Machine

OUR POPULAR PRODUCTS

Related Equipment

.png)